Logistics: What Differences Can Cobots Create?

It is no secret that numerous e-commerce companies depend on collaborative robots for vital delivery operations. Some might wonder if this is the peak era of these machines, is it possible that their significance will increase further? Well, all logical indicators point out in that direction.

Today and tomorrow

At present, robots and cobots are crucial to the operations of these companies. In the future, surviving without them will be next to impossible. If they do not make it impossible for companies to survive, absence of cobots will require herculean efforts for growth and development. Practically speaking, sincere, and committed corporations would not take a chance from staying away from them.

Giants Are Leading The Way

If you had any doubts about the viability of collaborative robots, getting to know the activities of Amazon Inc. will put them to rest. Most people are aware of the acquisition of Kiva Systems by Amazon Inc. in 2012. However, the fact that Amazon Inc. happily paid $US 775 million for the deal is not universally known.

It sounds incredible, but it is true. And this is one of the most excellent examples of the foresightedness of this leading e-commerce player. The efficiency of the logistics arms of Amazon Inc. witnessed numerous improvements post the acquisition of Kiva Systems. Their distribution centers became significantly productive with the use of advanced systems for fulfillment.

Amazon and Kiva- Impact of the Acquisition

There is very little doubt that a corporation of the standards of Kiva Systems’ would have developed the field further. They might have come up with substantially advanced and improved versions of their robotic systems. However, when Amazon Inc. bought Kiva Systems, they put the existing machines and cobots into serving themselves.

Substantial demands existed

Numerous other companies wanted to use the services of Kiva Systems. But that’s not how things turned out to be. It was not long before Kiva Systems was renamed as Amazon Robotics and the access of other companies to Kiva Systems’ technology was stopped completely.

However, the existing clients of Kiva Systems in 2012, continued using the services as per their contacts. Some of them are still dependent on Kiva Systems / Amazon Robotics. However, their contracts will not be extended. In 2-3 years, Amazon Robotics will be serving no clients other than Amazon Inc. and subsidiaries.

New players

Despite the exit of Kiva Systems, the advancements in relevant technology have not stagnated. New companies in the sector have emerged. They are trying their best to make inroads with existing as well as prospective clients. The flow of investment for research and development in these companies can create brilliant prospects in the times to come.

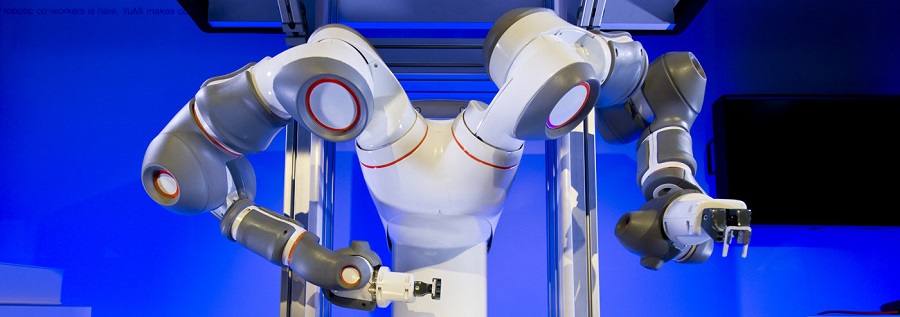

Cobots and deployments

If you analyze things from a statistical standpoint, you will find that more than 25 percent of cobots these days use AI. The improvement in the quality of the Industrial Internet of Things (IIoT) has made its presence felt.

Manufacturing and warehousing are two of the most prominent needs fulfilled by cobots with AI. They were the two sectors where cobots found substantial viable usage even in the early days. About 7-8 years ago, very few experts expected the use of cobots in data analytics. The present scenario has placed a lot of expectations on cobots, even for data analytics.

Packaging and cobots

The last few years have also witnessed an extensive proliferation of cobots in the packaging of products. The speed at which they can accomplish packaging-related tasks is the main reason behind this. The fact that they can get it done efficiently without any glitches makes them even more sought-after. Check Out Here – about more info of cobotic advancements in packaging and palletizing.

Status analysis

MNCs and other corporations with substantial turnovers in the logistics industry have not shied away from the use of advanced cobots. However, most mid-scale and small-scale organizations haven’t used the opportunity. They must understand that manual completion of warehousing tasks is not only decreasing their efficiency but also burdening them with high costs. The quicker they adapt to the changing landscape, the better it will be for them.